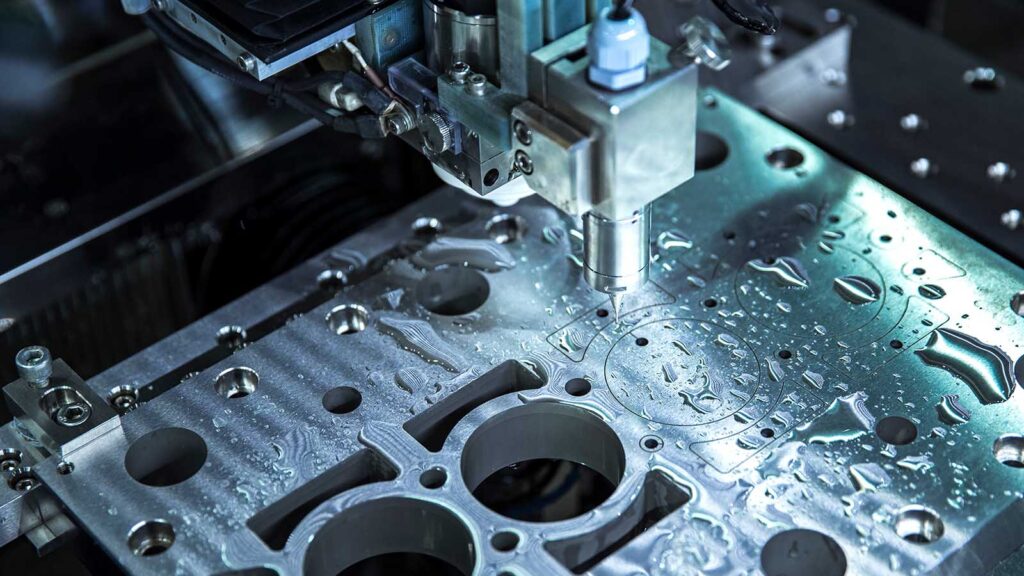

When it comes to manufacturing precision parts, relying on experienced CNC machining teams is essential for both high-volume and custom production orders. CNC machining, or computer numerical control machining, allows for the creation of complex, highly accurate components by automating the control of machining tools. The expertise of seasoned professionals ensures that every part produced meets stringent quality standards while adhering to tight tolerances. This reliability is crucial in industries such as aerospace, automotive, medical devices, and electronics, where the smallest deviation can compromise performance or safety. Experienced CNC machining teams bring a deep understanding of various materials, cutting tools, and machining processes. This knowledge allows them to optimize production methods, reduce waste, and enhance efficiency. Whether working with metals like aluminum, steel, titanium, or plastics, skilled machinists can select the appropriate techniques to maximize strength, durability, and surface finish. They also know how to troubleshoot challenges that arise during manufacturing, such as tool wear or material inconsistencies, which helps prevent costly delays and maintain smooth workflow.

For high-volume production, having an experienced team means the ability to scale operations while preserving consistency and quality. These teams are proficient in programming CNC machines to run multiple shifts and handle large batches with minimal supervision. Their expertise in setting up fixtures, calibrating equipment, and performing regular maintenance ensures that machines operate at peak performance. Additionally, they often implement rigorous quality control measures, including in-process inspections and final dimensional verification, to guarantee that every component aligns with specifications. This level of oversight is invaluable for customers who require dependable parts delivered on schedule. Custom production orders demand a different kind of precision and flexibility. Unlike mass production, custom machining projects often involve intricate designs, one-off prototypes, or small batch runs. Experienced CNC precision machined parts suppliers teams excel at interpreting detailed engineering drawings and CAD models to create bespoke parts that meet exact requirements. Their ability to quickly adapt machine programming and tooling setups allows for efficient turnaround times without sacrificing accuracy.

Communication and collaboration are also key strengths of veteran CNC machining teams. They work closely with clients, engineers, and designers to understand project goals and provide technical guidance. Uneed have choosing seasoned professionals, businesses can confidently navigate the complexities of modern machining, achieve efficient production workflows, and bring high-quality products to market on time. This partnership helps anticipate potential production challenges early and develop solutions that align with budget and timeline constraints. Experienced teams are familiar with industry standards and certifications, ensuring compliance with regulatory requirements when necessary. Their commitment to customer satisfaction is reflected in their responsiveness and willingness to make adjustments as projects evolve. Investing in a skilled CNC machining team translates into long-term benefits for manufacturers and product developers. It minimizes the risk of defects, rework, and wasted materials, all of which contribute to higher overall costs. It also accelerates the product development cycle by enabling rapid prototyping and iterative improvements. When precision, reliability, and flexibility are paramount, trusted CNC machining professionals provide a competitive advantage by delivering parts that perform exactly as intended.